to precision

For more than 40 years Mecasoft has specialised in precision machining by electro-erosion (or EDM) and other micro-mechanical techniques and traditional machining. We study, design and analyse the quality of all your metal parts projects, assemblies and machine tools. The result of our work also meets the highest requirements of the cutting-edge sectors in which we work.

A reliable partner who listens to you

Efficiency and competitiveness in support of your requirements

As a veritable one-stop-shop, Mecasoft accompanies its customers throughout every stage of their project. Thanks to this integrated partnership, we can ensure you coherence, efficiency, respect for your deadlines, quality of execution and monitoring of the result.

01. Mechanical techniques design office

Our micromechanics engineers offer you their expertise to draw up the most competitive plan of action offering the best performance. This plan of action is then implemented, from the design to the finished machined product.

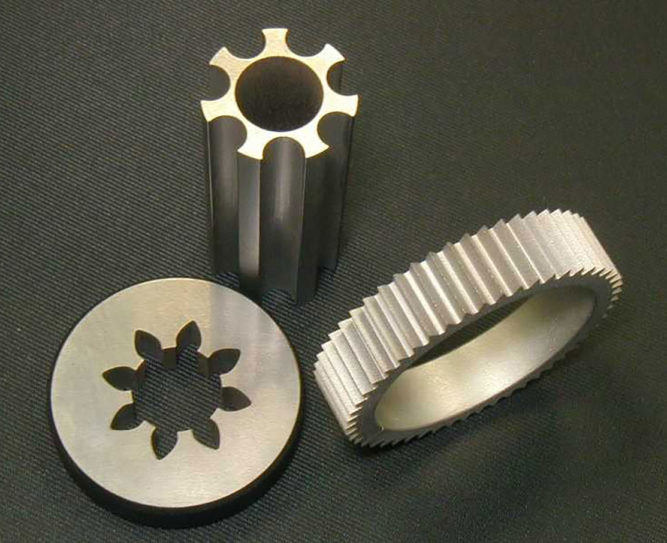

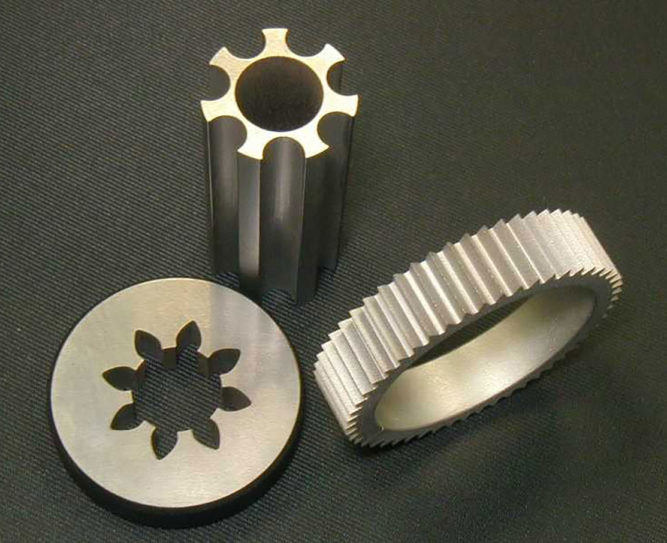

02. High precision machining

We carry out the machining of your metal components using classical machining processes as well as the most advanced electro-erosion, micro-mechanical and laser processes. Our expertise, combined with our efficient tools, enable us to design parts with the most complex and demanding profiles.

A vast and diversified range of machines also enable us to respond rapidly to your most urgent requests, offering our customers real flexibility.

03. Quality Control

Thanks to our 3D and visual inspection tools, we inspect and certify the quality of your finished product. We ensure that this corresponds with the established plan and the application requirements in your sector. When required, we can supply you with an inspection certificate.

01. Mechanical techniques design office

Our micromechanics engineers offer you their expertise to draw up the most competitive plan of action offering the best performance. This plan of action is then implemented, from the design to the finished machined product.

02. High precision machining

We carry out the machining of your metal components using classical machining processes as well as the most advanced electro-erosion, micro-mechanical and laser processes. Our expertise, combined with our efficient tools, enable us to design parts with the most complex and demanding profiles.

A vast and diversified range of machines also enable us to respond rapidly to your most urgent requests, offering our customers real flexibility.

03. Quality Control

Thanks to our 3D and visual inspection tools, we inspect and certify the quality of your finished product. We ensure that this corresponds with the established plan and the application requirements in your sector. When required, we can supply you with an inspection certificate.

Our line of business

Mecasoft makes high precision metal machining accessible to all sectors of industry, in particular those in which the parts, assemblies and tools demand an infinitely high level of accuracy, down to microns.

Aeronautics

We have received the trust of major customers in the field of aeronautics, such as Airbus, Boeing and Safran. They come to us for the design and manufacture of complex parts and strategic operations to be integrated in aircraft (in particular turbines), helicopters, drones, and other aerial devices. Mecasoft holds EN9100:2008 certification which ensures its customers a level of rigour that complies with the standards of the aeronautical sector.

Aerospace

Our EN9100:2008 certification is also applicable to the aerospace sector. Particularly demanding, this field requires a high degree of perfection in the design of complex metal parts. Mecasoft is active in the production of components for rockets and satellites and also in strategic and feasibility studies for these projects.

Defence

Mecasoft collaborates closely with customers in the defence field in strategic and design studies for their engineering products. In particular we work on machined parts used in building military vessels (submarines, ships, aircraft, helicopters, etc.) and their equipment. The perfection ensured by our technologies, backed up by EN9100:2008 certification has won us the trust of these customers for many years.

Precision industry

The electro-erosion and micro-mechanical processes employed by Mecasoft apply to all sectors of precision industry. We work using applications previously not available to general mechanics companies using classical technology. Our full accompaniment service ensures them extreme precision components in the fields of robotics, agro-food, instrumentation, nuclear, etc.

Medical & surgical

EDM techniques are very often used in the medical and surgical domain. They come into play for the design of various medical devices, machines and equipment. Mecasoft produces various components for implants, prostheses and instruments used in surgery and in the treatment of patients.

We respect the high demands of these applications while meeting the increasing desire to reject plastic disposal consumables in favour of sustainable metals.

Pharmaceutical

Our company is active in the pharmaceutical domain. We machine parts involved in the design of measurement and analysis tools and also in new opportunities in microfluidics. Mecasoft makes good use of its expertise in precision mechanics to produce the various classical and complex metal components found in pharmacological equipment.

Watchmaking, jewellery and luxury goods

The watchmaking industry requires high precision tools for the design, maintenance, repair and overhaul of its top-of-the-range products to ensure they have a long life. The quality of our machine pool and the knowhow of our engineers enables us to design these tools, as well as the particularly small and complex parts used in making watches, clocks, pendulums and any other component for clocks, silverware and jewellery.

Academic research institute

Mecasoft works in close collaboration with research institutes in order to study the feasibility of their projects and make the result viable. Via our mechanical techniques design office, we assist them in working out the best strategy and design prototypes using our proven technologies. In this way we have been contributing to technological and scientific developments for a long time, whether they are modest or large scale.

Automobile

Our micromechanical solutions and our other machining techniques are applied in particular to the development of parts for the automobile sector. For engine components and sensors, turbo injection systems and transmissions, gearboxes and clutches, in particular, we produce consistently accurate parts, often very complex, in series or even in industrial quantities.

Contact-us

Mecasoft, for the highest precision in micro-mechanics.

Rue de la Molignée 60

5537 ANHEE

Belgium

"*" indicates required fields