Whatever machining process is recommended for your mechanical part project, Mecasoft can offer you a solution: we are EN 9100 certified and are proficient in the numerous machining techniques within our company. Should this not be the case, we can call on trusted partners who are true experts in their areas of competence.

to precision

Your one-stop-shop, from the rough part to the finished product

When our design office prepares the plan of action for the design of your product, it determines the most suitable solution. It is often necessary to pass through the stages of shaping the rough part, using traditional machining techniques before using electro-erosion, micromechanics or laser processes for high precision cutting.

However, Mecasoft always takes overall charge of your project and will remain your unique point of contact. In this way, you will benefit from objective advice, consistent monitoring of your project, and quality control based on your specifications and the applicable standards. You will obtain a finished product that meets your requirements, completed with the shortest possible delivery time. All for the most competitive price and with complete peace of mind.

Traditional machining techniques

Machining consists in removing material from a rough part in order to give it the desired shape and size. The use of machine-tools provides sufficient force to shape the parts with a certain level of detail. Because of this, the results obtained using traditional techniques can be quite satisfactory for certain sectors. For others, a tighter precision will be expected.

We design mechanical parts for demanding sectors

01. Drilling

Drilling is one of the most common processes in machining. Using a rotating milling cutter or drill (or centre bit), a cylindrical hole is produced in the material. This is part drilled (blind hole) or right through with a higher or lower level of precision depending on the tool used. For stricter requirements, rapid drilling by erosion is recommended, or perhaps laser drilling, in order to produce micro drilling or micro holes.

02. Milling

Milling consists in producing a shape on a mechanical part by removing material. The principle is the combination of a rotating milling cutter, mounted on a milling machine that advances the part to be worked. Various shapes are possible such as cylindrical holes, grooves or other more complex shapes. This technique is often complementary to turning.

03. Turning

As with milling, turning consists in removing material from a part, in the form of turnings. The part to be worked is fixed to a rotating shaft. The cutting tool is then advanced to produce the desired cylindrical or conical shape. This technique is often complementary to milling.

Cutting is a variant of turning where the parts are machined from metal bars, in small, medium or large runs by automated turning.

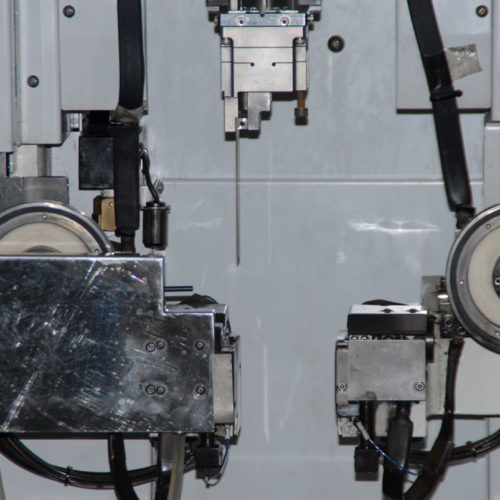

04. Combined turning-milling (5-axis CNC)

5-axis machining makes it very easy to produce complex parts. A 5-axis multidirectional machine tool (combining 3 linear axes and 2 rotating axes moving simultaneously) is capable of cutting on the whole surface of the part to be machined, combining the techniques of milling and turning.

This combination saves time by avoiding the removal or changing of tools. In addition, repositioning with the associated risk of errors is avoided.

The tightest precision, of the order of µm, is obtained by 5-axis milling by micro-erosion.

05. Laser cutting

A large amount of energy, in the form of a powerful laser, is beamed onto a small area of the material to be cut. The material in contact is then fused by the heat focussed on it, which causes cutting. This technique, used in various sectors of industry is suitable for thin materials and allows cutting of various materials giving precise cutting results.

06. Other techniques

Other machining techniques include, in particular, boring (to enlarge cut circular holes), grinding (or abrasion for finishing or shallow cuts), thread cutting (spiral with a threaded die) and tapping (the same but for internal diameters), and then broaching (consisting in enlarging a circular internal hole into a larger non-circular shape with a broach, or machining an external surface by the same technique).