Mecasoft is a recognised specialist in the field of high precision machining.

With 40 years in many sectors of state-of-the-art industry we can be trusted to manufacture mechanical parts with complex shapes.

Mecasoft is a recognised specialist in the field of high precision machining.

With 40 years in many sectors of state-of-the-art industry we can be trusted to manufacture mechanical parts with complex shapes.

Our techniques enable us to reach the perfect compromise between firstly competitiveness and secondly high precision. We evaluate the various possible steps together, at each stage of the project, in order to optimise the cost and quality.

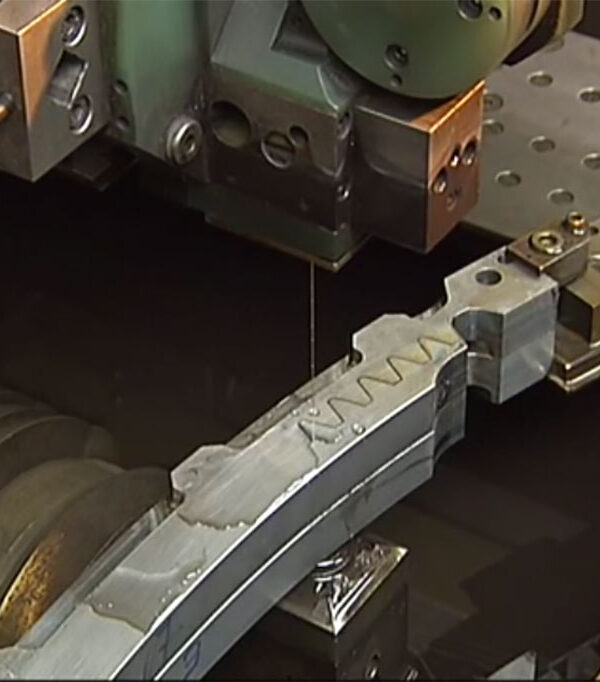

In this way, the most suitable techniques are implemented, depending, for example, on the tolerances desired, the complexity and size of the production run. For the most demanding stages, we offer a very high degree of precision in the manufacture of machined products. For these, we use electro-erosion in particular via three processes: by wire, by sinking and by drilling.

For the ultimate precision or when classical erosion reaches its limits, our knowhow was developed around different variants of micromechanics, such as micro-cutting, micro-drilling, micro-milling and micro-holes. Mecasoft is therefore one of the only European specialists able to master the technique of 3D, 5-axis micro-milling by electro-erosion.

The specific details of each of these processes enable us to respond to the wide range of requests of our customers who benefit, firstly from an optimum cost/performance ratio by choosing the most appropriate techniques and secondly, obtaining exceptional intrinsic quality for the most delicate stages, both when cutting and in the surface finish of the final product.

We are masters of high precision cutting for all types of conducting materials, even if very hard and tough: steel, titanium, aluminium, stainless steel 316L, copper, Inconel 605 or 718, titanium and tungsten carbide, etc. Thanks to a diversified machining pool, in particular in EDM, we handle both small and large scale parts for the design of prototypes, one-off or mass produced products, even in industrial quantities.

Mecasoft offers cutting, drilling and 3D surface texturing of your mechanical parts, with a precision measured in microns.

Mecasoft has a team of engineers and experts with many years’ experience of high precision machining. Each member of our staff benefits from an in-depth knowledge of the computer utilities we use and the characteristics of the equipment comprising our machine pool.

Each of them has successfully completed the Mecasoft internal training course. Due to his specific knowledge of each project, he can then maintain a true relationship of trust with our customer. In this way and through our mechanical design office, he always proposes the most suitable solution for the design of the part desired.

For its part, Mastery of utilities produces a finished result that is perfectly faithful to the established plan and with remarkable economic optimisation that is appreciated by our customers.

Thanks to our machines and perfectly mastered cutting techniques, our company has been successful in many collaborations in sectors that require mechanical tooling of irreproachable precision. These include players in aeronautics and aerospace and the medical sector. Mecasoft is in fact capable of meeting their special needs and addressing the specific constraints of each of these state-of-the-art sectors.

See non-exhaustive list of sectors for which we design and produce machined components. Whatever your field or the nature of your product, make contact with our team who will be able to find a solution to your request.